How do people truly learn in the flow of work? The stories here illustrate why it is important to encourage workers to “figure it out” when implementing and applying workflow learning.

A revealing question

In my consulting, I work with many clients and other learning and development (L&D) professionals. I frequently ask them how workers would produce results if there were no training programs.

I consistently hear that workers would:

- Do trial and error

- Check with each other

- Refer to past experience

- Review logs, records, and documentation

- Check suppliers and other sources

Some people have misgivings about these approaches, arguing that:

- Workers won’t know the correct answers

- Work is done inconsistently

- There are higher risks

- There will be no quality control

However, the consensus is that the workers will figure it out.

What does “figure it out” mean?

Curious about what it means when workers are expected to figure things out, I asked workers, “If you have a broken part or a problem at work, what do you do?”

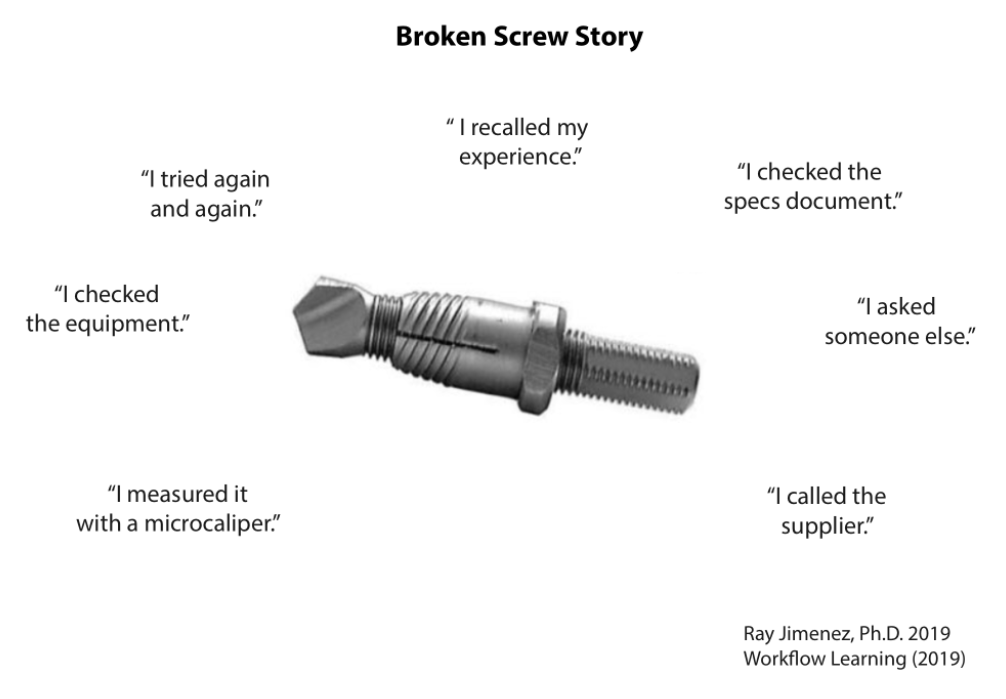

The “Broken Screw” story illustrates this idea.

A technician, having a problem her equipment, scans the manual again to see if she’s doing the procedure correctly. She thinks, “I’m using the correct screw, but it won’t fit. What am I doing wrong?”

She tries to insert it again, but to no avail. She checks the supplier’s website for more updated information about the equipment but there was none. Her last resort is to ask a senior technician about it.

He replies, “You have to heat it up a bit. Although this is supposed to be the right screw, it does not fit.”

Figure 1: Workers try many approaches to fix the “broken screw”

Figure 1: Workers try many approaches to fix the “broken screw”

My initial reaction was: If workers could figure out the solution, why focus effort on producing training content? Shouldn’t we help workers master the art of “figuring it out”?

Now questioning my own focus as an L&D professional, I pursued the question with clients, workshop participants, other L&D professionals, and operations people.

Three companies; one common denominator

A few years ago, I was creating troubleshooting and problem-solving courses for one of the world’s largest fiber optics cable manufacturing operations. I wondered why these highly educated engineers and technicians needed help solving problems.

- The client provided insight: “The operation is pretty automated. However, we discovered that when unexpected deviations caused problems, workers were slow to think through the issues and find solutions. Hence, wastage increased. Bottlenecks happened. Production slumped. We wanted them to be able to address the unexpected.”

In an oil refinery project, the VP for operations raised a challenge: What would it take for our people to reduce errors by 1 percent?

- The VP wondered why many workers don’t go beyond the obvious. Pumps usually go through regular checks and function well. But they may develop minute and invisible cracks, which are unnoticed during observations and instrument testing. These grow into costly and time-consuming problems. Even so, workers seem content to rely on routine records and visual inspections. They don’t anticipate and prevent hard-to-find errors and problems.

I worked with an executive to retool and add robotics to the manufacturing process for a truck chassis.

- The executive told me that this expanded their production capacities. However, indispensable as robotics are, he still needed people to be able to think through issues and make decisions during breakdowns.

The common denominator: Employees need to be able to anticipate uncommon events and find solutions.

A framework for understanding: The Workflow Diagnostic Process

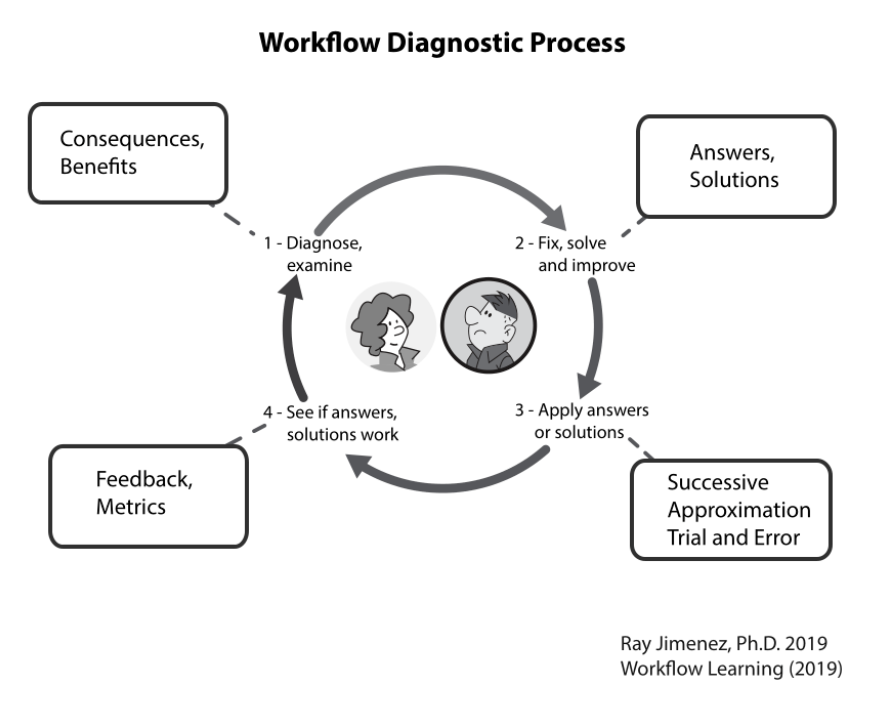

The Workflow Diagnostic Process evolved from these experiences of working with different companies. This framework helps me make sense of workers’ ability to “figure it out.” Figure 2 summarizes the process.

Figure 2: The Workflow Diagnostic Process is a continuous cycle of diagnosing problems, finding and testing solutions, and gathering feedback on those solutions

Figure 2: The Workflow Diagnostic Process is a continuous cycle of diagnosing problems, finding and testing solutions, and gathering feedback on those solutions

In the workflow, workers:

- Constantly diagnose, fix, solve, and improve their work. The diagnostic process is the act of “figuring it out.”

- Seek answers through experience sharing; examining logs, records, and databases; trying software solutions; and consulting suppliers.

- Experiment; use trial and error.

- Use feedback from data, analytics, or observable indications to check whether their approach worked.

The Workflow Diagnostic Process happens in seconds and is constantly repeating. When workers fix, solve, and improve issues, they directly impact work outcomes. Therefore, workflow learning is learning at work that directly impacts outcomes.

The challenge that we face in L&D is that many of our training programs are far removed from the realities of work. We must bring our programs closer and find new ways to help workers learn while doing their work. This means we need to embrace and nurture their ability to “figure it out” using the Workflow Diagnostic Process.

Turning concepts into processes

The next big question was how to convert this insight into a process that would help L&D clients and operations leaders.

Experience-sharing between workers, on its own, is insufficient.

The quality of outcomes and pace of problem-solving accelerate when workers go through a thinking process. This improves their ability to deal with the unknown and unexpected. Asking reflective questions such as “What would happen if you tried it this way?” develops deeper thinking skills in workers.

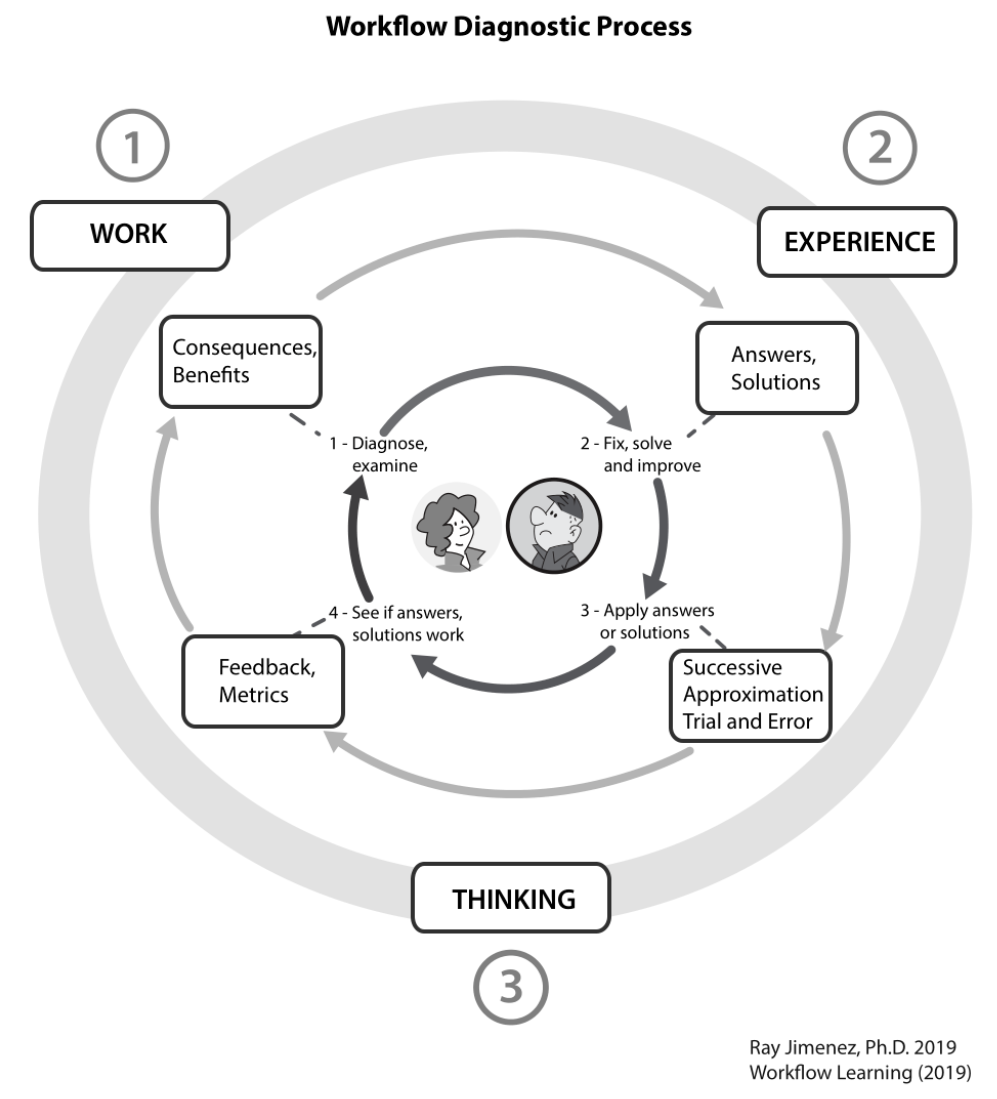

With this in mind, I added work, experience, and thinking into the Workflow Diagnostic Process.

Figure 3: Adding work, experience, and thinking into the diagnostic process brings learning closer to work

Figure 3: Adding work, experience, and thinking into the diagnostic process brings learning closer to work

- Workflow learning starts with work. Workers identify the real work issues and situations they want to fix, solve, or improve—they “own” the issues and solutions. To bring learning closer to work, this is essential.

- Workflow learning promotes experience-sharing—the fastest, cheapest, and most reliable way to find answers and solutions.

- Workflow learning encourages thinking processes that elevate experience from open-ended conversations into guided and directed inquiries and logical solutions. Critical thinking helps remove bias, encourages workers to think outside of their silos, and promotes deeper learning.

Workflow learning helps workers “figure it out”

Workflow learning supports and assists workers while they are in the process of “figuring it out.” This approach compels us to think beyond traditional approaches to instruction so that we achieve our main mission: Through Work We Learn.

David Scott, a learning leader at the NASA Huntsville Operations Support Center (HOSC) in Alabama, recently summed it up: “When workers are ‘figuring it out’—fixing, solving, or improving on a work problem, sharing experiences, and using thinking tools—they are learning without knowing they are learning.”

Take eLearning beyond instruction

Learn how to implement the Workflow Diagnostic Process and support workers as they “figure it out.” Register today for “Boots on the Ground—Implementing Workflow Learning,” a daylong workshop presented by Ray Jimenez, PhD. This pre-conference workshop takes place October 22, ahead of DevLearn 2019 Conference and Expo, October 23–25 in Las Vegas.

Resources

A New Paradigm for Corporate Learning: Learning in the Flow of Work by Josh Bersin

Mastering the Learning Pyramid by John Hagel

Prediction: Learning Will Go to Where Work Happens by Julie Hiipakka

Work-Based Learning: Bridging Knowledge and Action in the Workplace by Joseph Raelin