There are people who invent useful and profitable products, and there are people who perform the manufacturing, distribution, and record-keeping related to those products. Once these operations and the personnel required to manage them grow in complexity, so does the chance of losing the vital organizational knowledge associated with core knowledge and processes. This was the case with a small manufacturing company that enlisted the help of IQStrategix to recapture its corporate knowledge.

It does not matter if an organization is large or small; the IQStrategix process of identifying and retrieving vital organizational knowledge buried deep within organizational structures is the same. The differences between a small and large knowledge base and its eLearning functions are simply the number and complexity of those structures, and thus the time and effort it takes to successfully regain knowledge control.

What makes the following project interesting is that, in addition to the knowledge recovery process, IQStrategix’s team also taught the company manager the art and science of knowledge engineering. Her mastery of the discipline went from zero to accomplished as she worked part-time on the project until it was completed. She now maintains and advances her company’s knowledge ecosystem without outside help.

IQxCloud use case: Background

“ABC Manufacturing” is a small manufacturing company that provides products to a niche customer base. (I changed the company’s name in this article to protect its identity, due to the sensitivity of its market.) ABC is a family–owned and operated company that has been in business for many years. Like most small manufacturing companies, there has been little turnover among its managers and employees over the life of the business.

ABC owns and operates numerous special-purpose machines, it buys its manufacturing materials and supplies from regional vendors, and it farms out specialized fused-part processing to ISO-certified subcontractors. The operation runs smoothly, yet management felt there was a deep threat looming on the horizon because ABC’s chief machinist, who has most of the manufacturing processes in his brain, was getting older and had some minor medical problems.

ABC’s manager also realized that there was a deep reservoir of “production knowledge” she did not know or understand, making it unlikely that she would be able to successfully hire and train a new machinist to run the manufacturing side of the business in the event her chief machinist left the company. This knowledge deficit problem presented a hidden threat to the family business, just as it does to tens of thousands of manufacturers around the world who are faced with the same situation regardless of their size and staffing.

IQxCloud knowledge engineering content curation process

After the initial introduction and engagement process, IQStrategix’s Martha Nawrocki was flown in to assess the knowledge deficit problem by defining the scope and recovery process for the project. Martha first understood how the management, marketing, and manufacturing efforts functioned together; then, she focused on the manufacturing of ABC’s 63 products. During this process, she learned that the manufacturing process required 6 – 12 procedural steps for each part.

Other information requirements were:

- Number of machines—14

- Documentation—Most of the machine settings and procedures used by the machinist were recalled from his memory as they were required. Available documentation was over 20 years old with hand-written annotations on tolerance settings, which had to be verified for accuracy against current requirements. The production process included ordering base materials from suppliers, multiple in-house machine processing steps, outsourcing specialized production processes to third parties, staff quality control inspections for each major step, and inventory control for finished products.

- Operating and maintenance manuals—There were only six machine manuals in-house. The rest had to be located on the Internet and uploaded to the knowledge ecosystem.

As Martha and ABC’s manager reviewed the resource materials, the importance of restoring the company’s lost knowledge became obvious—lose the machinist, lose the company. ABC’s manager immediately went to work on the file cabinet, updating and digitizing the product production procedures. She used Excel files to organize required resources. The manager then “interviewed” her machinist. Rather than just asking questions, she documented every step he took in the setup and manufacturing of each machine and part while in production.

Working remotely, Martha then helped ABC’s manager to identify other areas that needed documentation. These included:

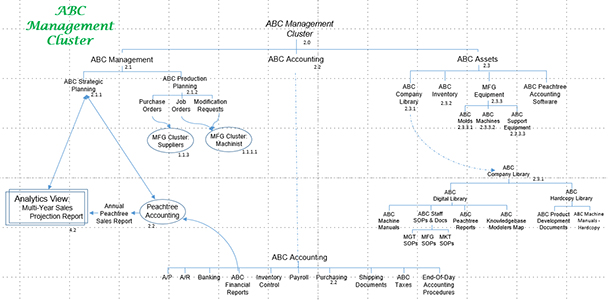

- Management Resource Cluster—Strategic planning and annual production planning, accounting, asset identification, and the reordering of ABC’s digital and hard copy library.

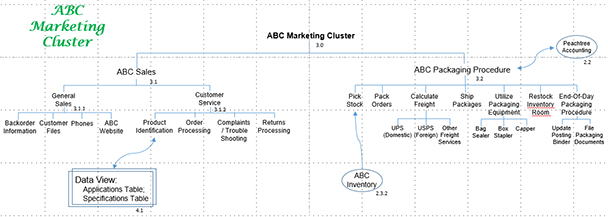

- Marketing Resource Cluster—Customer sales procedures, customer/product identification, and product shipping and handling sequences (worldwide).

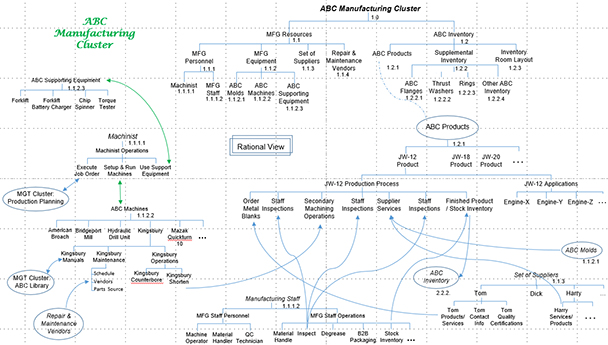

- Manufacturing Resource Cluster—Set of suppliers, in-house machines (manuals, identity, and functions), repair and maintenance vendors, machinist tasks, manufacturing staff operations, and molds.

During the discovery process, Martha also learned that, for the most part, ABC’s manufacturing and quality assurance standards and procedures complied with ISO (International Standards Organization) standards, but the company had not sufficiently gathered and recorded this information to prove its processes and procedures as required for ISO certification. It was clear to Martha that by digitizing the content and procedures, a major part of ABC’s knowledge reclamation goal could be met and ISO certification obtained, though not currently required.

IQStrategix organizational front office modeling solution

As the ABC project illustrates, organizational knowledge is deeply intertwined. Discrete processes and procedures related to one department or operational function usually cross the lines to another department or function as illustrated herein: management, marketing, sales, customer relations, accounting, and manufacturing.

Given this, front office processes and procedure activities need to be aligned with back-end processes and procedures to achieve the greatest value from organizational structures. This is especially true since it is these processes that can easily impact the profitability of a business.

ABC’s wholesale customer sales procedure, for example, includes counseling customers on which products might be best suited for their markets. This single procedure was easily conducted by the office manager, given her years of experience, but it would be very difficult for a new person to perform the same function if they lacked the office manager’s depth of knowledge about ABC products. The complexity of the product identification process would simply be too overwhelming for a new person to discuss in a normal, free-flow sales conversation.

After automating the product identification procedure in IQxCloud, the product sort-and-recommend function could walk a new person through a step-by-step procedure that is both intuitive and effective. It also provides a “what-if” capability that identifies related applications for a selected product, which could lead to greater sales of ABC’s products. A hidden advantage of the real-time product sort-and-find process is that a new person could easily conduct an ordering process more professionally and accurately than if he or she were using the previous manual system. Other similar processes and functions were also modeled as illustrated in Figures 1 – 4, which together compose the ABC Knowledge Ecosystem Modeler’s Map.

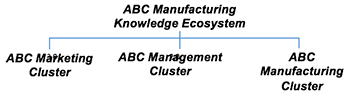

Figure 1: Overview of the ABC Manufacturing Knowledge Ecosystem

Figure 2: The ABC Management Cluster

Figure 3: The ABC Marketing Cluster

Figure 4: The ABC Manufacturing Cluster

The IQxCloud knowledge ecosystem development solution

The knowledge ecosystem development process proceeded as follows:

- ABC’s manager provided the digitized source materials for the project, such as product pictures, schematics, tolerances, operating and maintenance manuals, videos, and other production materials included in the ABC project. She also developed over 20 standard operating procedures for her office staff—rounding out the knowledge she wished to include in the ABC knowledge ecosystem.

- Martha identified all of the required rational patterns of thought (processes and procedures), which could then be modeled as compositions, taxonomies, sequences, sets, and so forth. These were outlined in a Word file. The IQxCloud model approach, used throughout the knowledge ecosystem, provides a natural consistency of presentation that is both rational and user-friendly.

- All the words, phrases, and symbols used in ABC’s business were listed in an Excel spreadsheet, defined with descriptors to disambiguate same spelling and heterogeneous terms. No concept model or document is ever duplicated.

- The list of Excel concepts was then uploaded into IQxCloud using the systems’ “FastEdit” function.

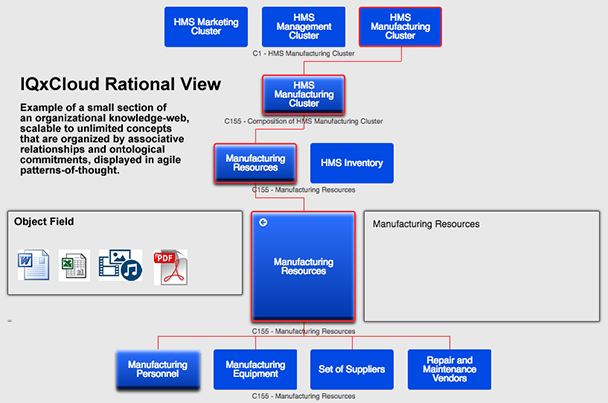

- The Word model outline was then uploaded into the IQxCloud “Builder” component, which immediately populated a set of buttons in what is called the “Rational View,” a functional view of the IQxCloud browser component. There are several views, however; the Rational View is one of the most used interface views. A small fragment of the Rational View screen is shown in Figure 5.

Figure 5: Rational View

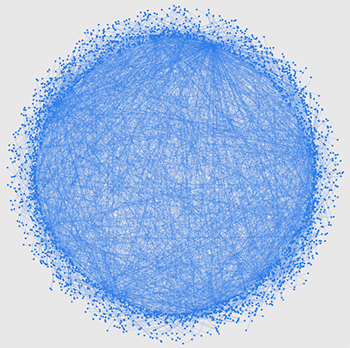

Seen from a detailed concept perspective, the IQxCloud back end organizes concepts based on their associative relationships as opposed to conventional structured indexing. As a result, users can click from one concept to another throughout the knowledge ecosystem. See Figures 6 and 7.

Figure 6: Organizational Knowledge Ecosystem

Figure 7: Concept detail of organizational knowledge ecosystem

Conclusion

ABC Manufacturing’s primary goal was to recover its operation’s lost knowledge. In the end, the company not only regained the knowledge it had lost, but it also gained a real-time eLearning environment that novice users could access to rapidly learn ABC’s proven processes and procedures. An analytic product find/sort function was also implemented to assist new customer service representatives to rapidly find ABC’s 63 products and intelligently converse about them.

Though ABC represents a small-scale example of a knowledge management and eLearning ecosystem, its principles can be applied and scaled to very large, multi-location, multi-country, multi-language organizations. As one knowledge ecosystem is defined and modeled, it can be layered onto existing knowledge ecosystems to accommodate HQ, division, department, unit, project, and every related function and task associated with those entities.